The biopharmaceutical industry is experiencing a profound transformation with the advent of single-use bioprocessing technologies. As the demand for biologics, vaccines, and personalized medicine continues to increase, manufacturers are shifting from more traditional methods of bioprocessing to more efficient, cost-effective, and flexible solutions. The development of new therapeutic modalities, such as cell and gene therapies, and the increasing success of clinical trials fuel the growth in the single-use bioprocessing market.

Understanding Single-use Bioprocessing

Single-use bioprocessing, also known as disposable bioprocessing, involves the use of pre-sterilized, single-use components and systems that are primarily made from plastic. The components, which include bioreactors, mixers, connectors, and tubing, are designed for single use and then discarded. This property of single-use differs fundamentally from the traditional stainless-steel systems that require extensive cleaning and sterilization between uses.

Market Growth and Dynamics

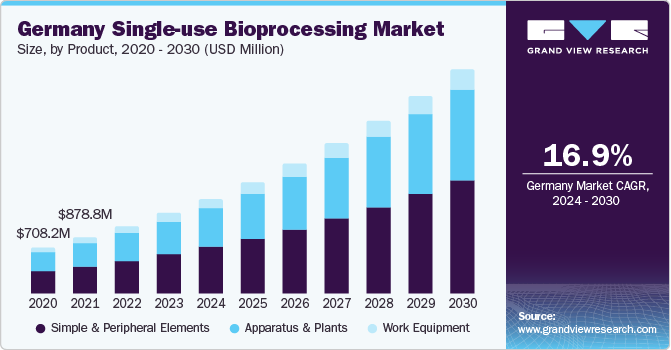

The global market for single-use bioprocessing has been witnessing remarkable growth. According to a recent report from Grand View Research, this sector is anticipated to reach USD 80.13 billion by 2030, growing at a compound annual growth rate (CAGR) of around 16.24% from 2024 to 2030. Several factors contribute to this rapid expansion:

Cost Efficiency: Single-use systems significantly reduce capital and operational costs. They eliminate the need for expensive cleaning and sterilization processes, reducing labor and downtime between production runs.

Flexibility and Scalability: Single-use technologies provide significant flexibility, allowing manufacturers to quickly switch between products and adjust production according to the demand. This is particularly advantageous for smaller batches of personalized medicines and rapidly produced vaccines.

Reduced Risk of Contamination: The use of disposable components minimizes the risk of cross-contamination and enhances sterility, a very important factor in biopharmaceutical production.

Faster Time to Market: Single-use systems streamline the setup and validation processes, enabling faster initiation of production. This is crucial in the development of new therapeutics where speed is essential.

Gather more insights about the market drivers, restrains and growth of the Single-use Bioprocessing Market

Key Applications and Segments

Single-use bioprocessing technologies are employed across various stages of biopharmaceutical production:

Upstream processing refers to the early stages of biomanufacturing, where cells and organisms are grown to create a biological product. This process is crucial because it sets the foundation for the quality and quantity of the final therapeutic product.

In this phase, single-use bioreactors and mixers are commonly employed. These tools are designed to be used once and then disposed of, which helps prevent contamination and saves time that would otherwise be spent cleaning and sterilizing reusable equipment.

Downstream processing is a term used in biomanufacturing to describe the steps that come after the initial production of biological materials, such as cells or proteins. This stage is all about purifying and preparing the product so it’s safe and effective for use.

Fill-finish operations are the very last stage in the biomanufacturing process. This is where the biological product, now fully developed and purified, is placed into its final packaging, which could be vials, syringes, or other types of containers. Therefore, these operations are a vital step in ensuring that biologic products are safe and effective when they reach patients.

Challenges and Considerations

Single-use bioprocessing brings a host of benefits, but it also comes with its own set of challenges. One major concern is the environmental impact of disposing of single-use plastics. The accumulation of plastic waste is a serious global issue, and the bioprocessing industry is also not an exception to this problem.

Various initiatives are being undertaken within the industry to shift towards more sustainable practices, which include the implementation of recycling programs and the research into biodegradable alternatives that can minimize the ecological footprint.

Another significant challenge is in ensuring that the materials used in manufacture do not adversely affect or contaminate the biological products they come into contact with. It is crucial that these single-use materials are compatible and do not compromise the quality of the product. This necessitates thorough testing and validation processes. In addition, the lack of standardization across single-use components can complicate the supply chain, making it difficult to ensure a steady provision of necessary materials. To overcome this, there is a need for industry-wide collaboration to establish common standards. Finally, while single-use systems may reduce operational costs, they require a significant initial outlay. Companies must weigh these upfront costs against the potential long-term savings and benefits to determine if the investment is sound.

Future Outlook

The future of the single-use bioprocessing market looks promising, driven by continuous advancements and innovations. Integrating automation and digital monitoring systems into single-use platforms is improving process management and data analysis, resulting in production that is both more effective and dependable. Single-use systems are being utilized in areas beyond conventional biologics, encompassing cell and gene therapies that necessitate highly specialized and flexible manufacturing processes. Partnerships between biopharmaceutical companies, technology providers, and regulatory bodies are enhancing the development of next-generation single-use solutions that address current limitations and anticipate future needs.

Browse more reports published by Grand View Research.

- Blockchain Technology Market Size, Share & Trends Analysis Report By Type, By Component, By Application, By Enterprise Size, By End-use, By Offering, By Region, And Segment Forecasts, 2024 – 2030

- Robotaxi Market Size, Share & Trends Analysis Report By Propulsion (Electric, Fuel Cell), By Application (Goods Transportation, Passenger Transportation), By Component (Camera, RADAR, LiDAR), By Region, And Segment Forecasts, 2023 To 2030

Conclusion

Single-use bioprocessing is revolutionizing the biopharmaceutical industry by offering flexible, cost-effective, and efficient solutions for the production of biologics. As the market continues to grow and evolve, the adoption of these technologies will be crucial for companies aiming to stay competitive and meet the ever-increasing demand for innovative therapeutics. By addressing challenges and utilizing emerging trends, the single-use bioprocessing market is pivotal in shaping the future of healthcare.